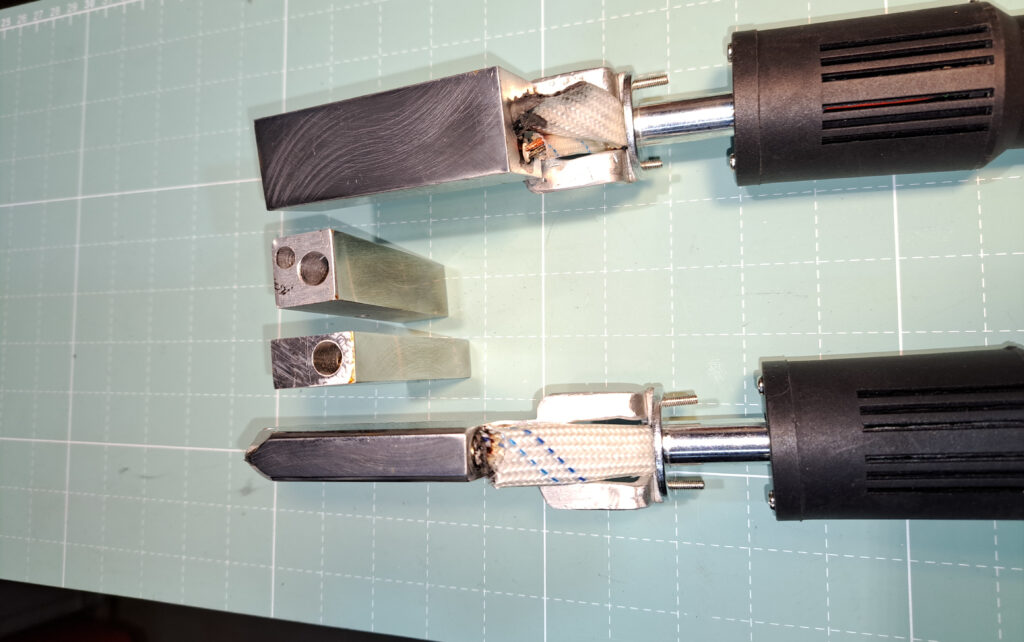

Michael from Hamburg, Germany, emailed to show me how he cleverly modified his heat sealing iron by replacing the rounded aluminum foot with interchangeable feet he fabricated out of scrap aluminum. Well done, Michael! This is the type of DIY genius that needs to be shared.

If you have some rudimentary metalworking tools, such as files, a drill, a vice, a hack saw, and a tap and die set, then this is a really clever alternative to simply flattening the bottom of the stock leather iron’s foot (which is what I’ve been recommending). It might take a bit longer to fabricate your own parts, but as Michael shows, you won’t be limited to a single foot, and that opens up new possibilities for ironing seams of different widths and configurations. You could even design a foot that pivots so you can press straight down with the iron, which would be easier on your wrist if you’re doing a lot of heat sealing.

Check out Michael’s page where he shows detailed photos of the parts he fabricated out of scrap aluminum bar, and how they fit together.

If I can figure out a way to make parts like this quickly enough that selling them for a reasonable price becomes economical, I might consider doing that, or if someone else wants to give it a shot then I would be happy to point people in their direction…

2 Comments

Michael · February 25, 2025 at 3:57 pm

Hi, Michael here…

Thank you Matt for sharing my idea with your website visitors, I really appreciate it.

All you need for the foot is a simple aluminium square profile. You can get it relatively cheaply online. The sheet metal comes from a DIY store, but you can certainly also get it online in small dimensions.

If you are unsure where to drill the holes for the heating rod and the sensor, it is best to use the original base of the iron as a reference.

Please ensure that the electrical cables are well protected against contact with the aluminium parts. A short circuit could possibly destroy the electronics.

Matt (Admin) · February 25, 2025 at 4:47 pm

Thanks for the tips, Michael 🙂