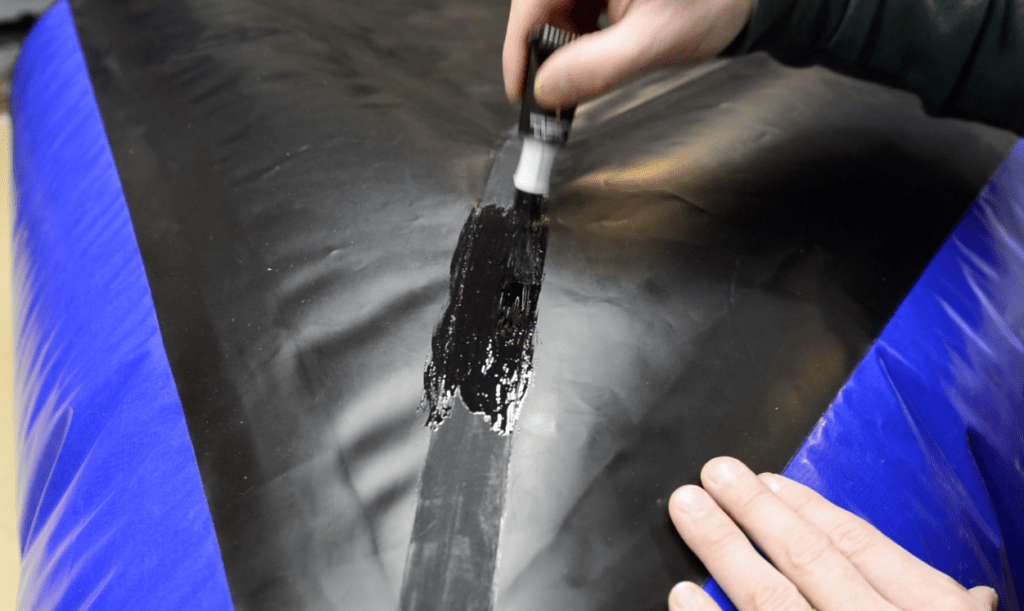

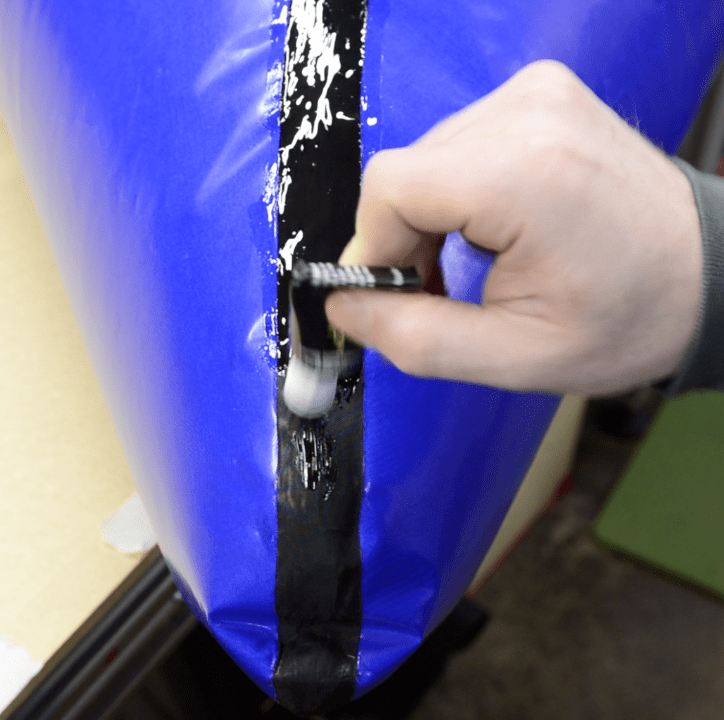

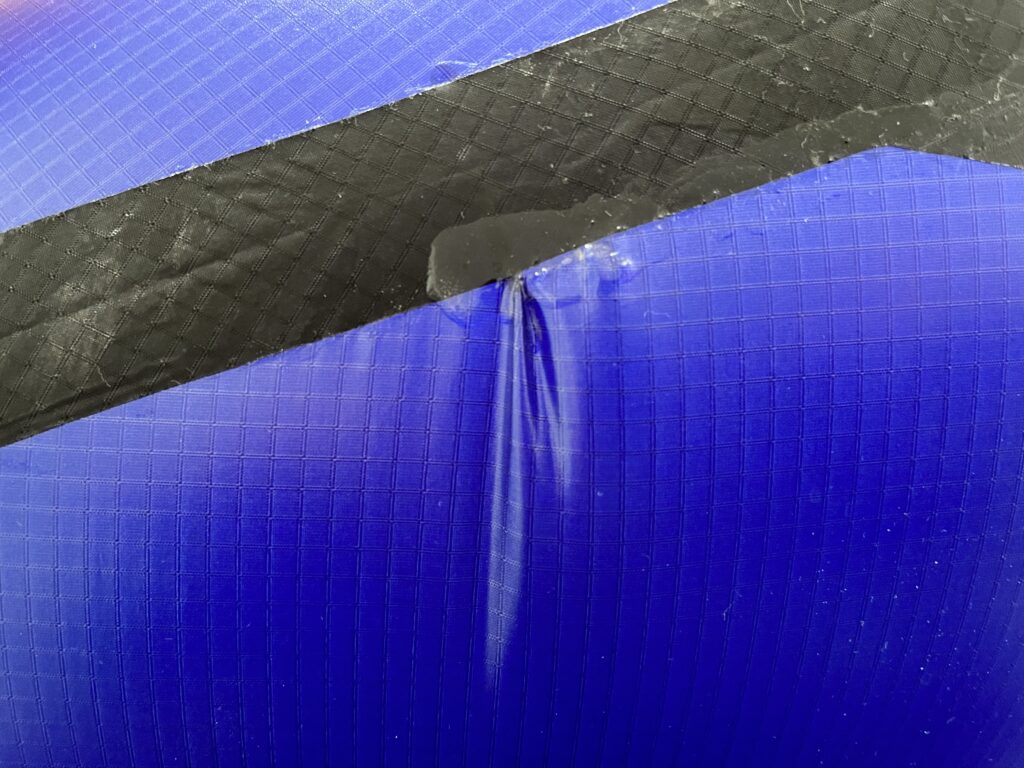

Your packraft’s seam strips will experience scrapes and abrasion, especially where they wrap under the floor, and possibly where your shoes rub against them. Coat high abrasion areas with Seam Grip+WP or Aquaseal or Aquasure to ensure they won’t start to peel like the seam in the photo below, or to prevent it from getting worse. You don’t have to coat the entirety of each seam, but at a minimum you should coat the seams where they are exposed below the waterline.

Note: never use Seam Grip+SIL silicone tent sealant on a packraft.

Personally, I usually coat just the part of the seam strips that are below the waterline (plus the part of the rear center seam that can’t be sealed from the inside unless a zipper is installed in the boat). Then I keep an eye on them over the months and years, and if the edges start to fray I consider applying sealant then.

Tips:

- It’s easier to apply sealant to an inflated packraft.

- Make sure the fabric is clean and free of soap or tape residue before applying the sealant.

- Spread the sealant a few mm past the edges of the seam strips (it won’t darken the fabric on the outside of the packraft).

- You can also apply the sealant to the reinforcing strips around the inside of the cockpit, if you like (though it’s not required). This will prevent them from soaking up any water.

- After applying sealant to areas where the tubes join the floor inside the cockpit (along and between the reinforcing strips), invert the packraft and suspend it by draping it over something so it is suspended by the floor fabric. This will pull the floor fabric away from the tubes and will allow the sealant to cure without them touching. After it’s dry, dust these areas with talc so the sealant won’t stick to itself.

- The sealant will feel dry and will be functional after about eight hours, but it takes several days for the sealant to cure to the point where it won’t stick to itself. If you allow the sealant to cure completely before use (leaving your packraft inflated for several days) then dust and debris won’t stick to it and it will have a nice glossy surface – at least until you scuff it up. If you need to roll up the packraft before the sealant can cure completely, rub some talcum powder on the surface of the sealant so it won’t stick to itself – note however that the talc will create a dull, matte surface on the sealant instead of a glossy sheen.

This page is shared between several instruction sets – please use the Back button to navigate back to the instructions for your kit.

Questions? Leave a comment below!

0 Comments