Approximate time: 3 hours

These instructions are for assembling the spray deck kit, available to fit the newer single-person DIY Packrafts. The spray deck is added after the packraft is otherwise complete.

Spray Deck Kit Parts Checklist:

- One long piece of colored plastic tubing, about 2.5 meters (~98″) long (for stiffening the cockpit coaming)

- Fabric – a single piece of black fabric with shapes scored into it. One corner of the fabric is labelled with “SD” (Spray Deck) and the abbreviation for the packraft model and size:

- “SD-A-120” is a spray deck for an Atlin, 120 cm (47″) size

- “SD-A-133” is a spray deck for an Atlin, 133 cm (52″) size

- “SD-A-145” is a spray deck for an Atlin, 145 cm (57″) size

- “SD-S-120” is a spray deck for a Skeena, 120 cm (47″) size

- “SD-S-130” is a spray deck for a Skeena, 130 cm (51″) size

- “SD-S-140” is a spray deck for a Skeena, 140 cm (55″) size

- “SD-T-120” is a spray deck for a Telkwa, 120 cm (47″) size

- “SD-T-130” is a spray deck for a Telkwa, 130 cm (51″) size

- “SD-T-140” is a spray deck for a Telkwa, 140 cm (55″) size

- “SD-Other” has only the coaming components scored into the fabric and the remaining fabric can be sized to fit other packrafts

- One short piece of black plastic tubing, roughly 4-5 cm (~2″) long, sized to fit inside the long plastic tube (to act as a connector). This was added to the kit in early 2021 – if your kit does not include a connector, you can make one out of 8 mm plastic tubing, wooden dowel, or something similar (or if you’re ordering something else from DIY Packraft in the future, ask me to include a connector in your shipment for free).

- Note: spray skirt kits are sold separately

Note: The “coaming” is the rim around the spray deck’s cockpit hole, and it’s basically a fabric tube stiffened by a semi-rigid plastic tube inside it. The coaming keeps water from flowing into the cockpit and it’s what the spray skirt fits over.

Assembly Instructions:

Note: If you want to make a removable spray deck, visit this page after you’ve familiarized yourself with the instructions here.

Start by separating the fabric pieces, using scissors to follow the scored lines.

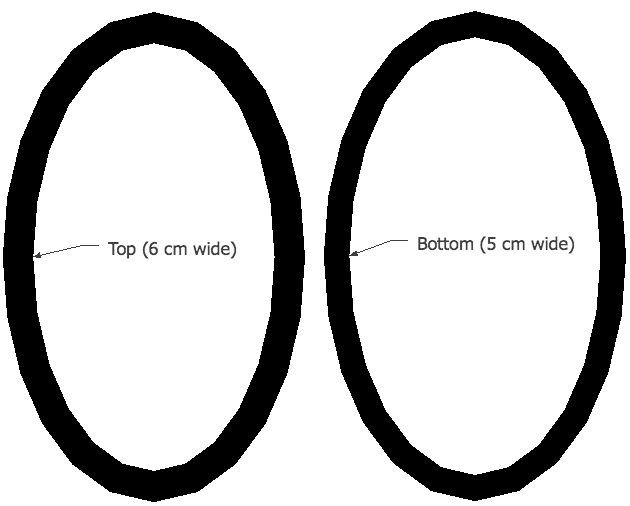

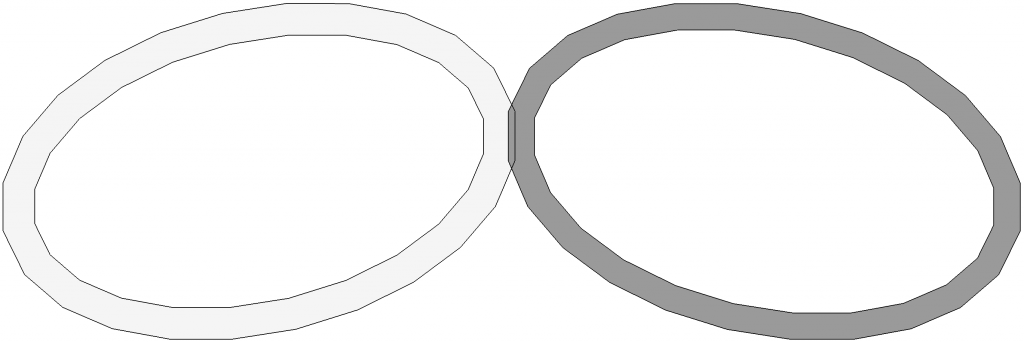

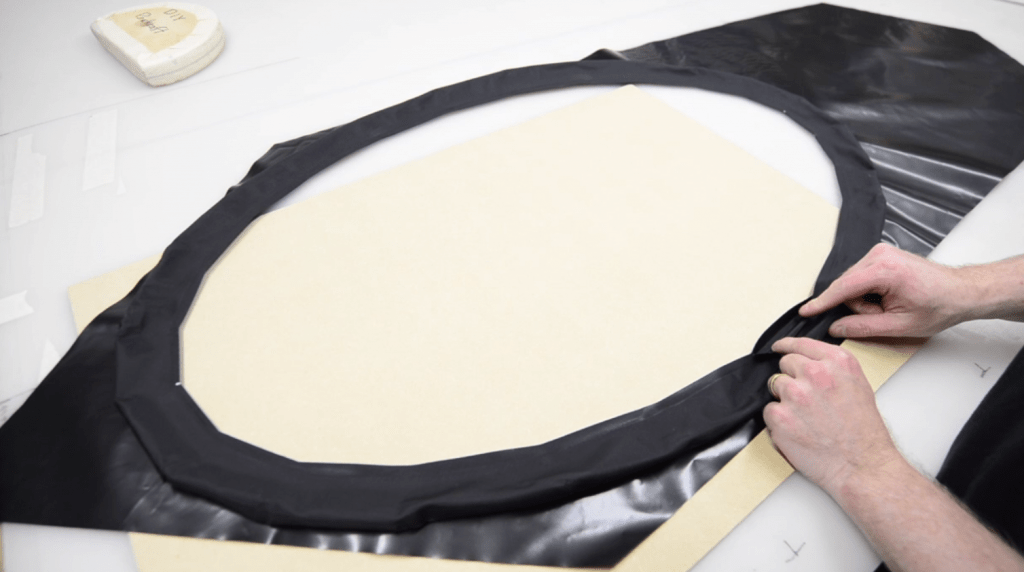

Lay out the oval-shaped fabric rings and mark the center line on the TPU side of each one.

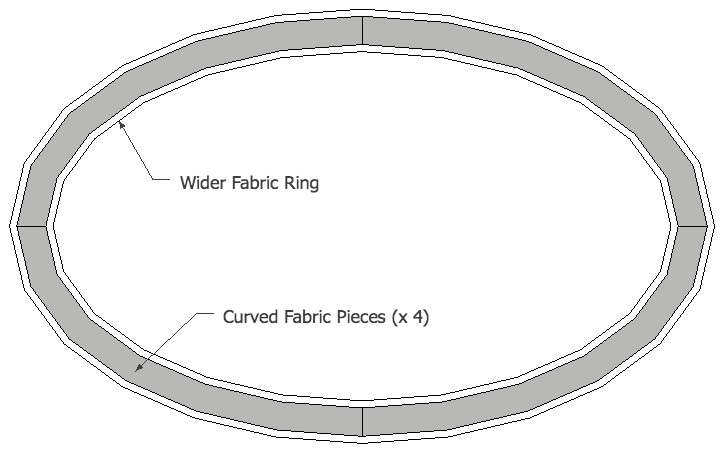

Lay out the wider ring with the TPU (shiny) side up. Arrange the four curved (j-shaped) fabric pieces over the wider ring, TPU side down, so there’s 1 cm of TPU exposed on each side of the curved pieces. Use your iron to tack each piece in place and then heat seal the four curved pieces to the ring, being careful to keep them centered as you go. (Note: These welds don’t have to be perfect – these pieces aren’t structural, they just provide a slipperier surface inside the coaming tunnel so the stiffener tube will slide in and out more easily.)

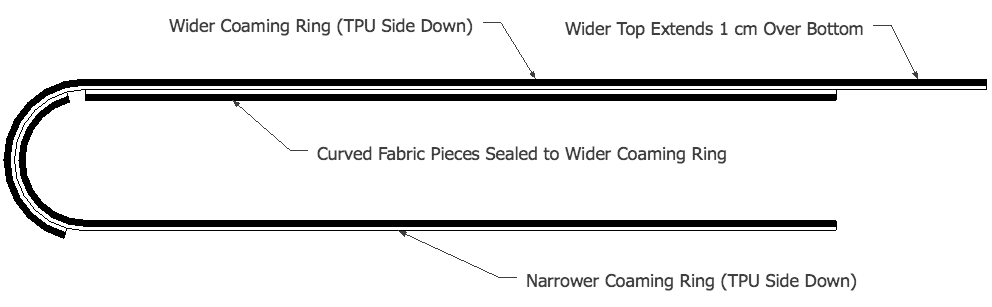

Next we’re going to seal the edges of the two coaming rings together so they form a single ring with a C-shaped cross-section – shaped sort of like a bicycle tire.

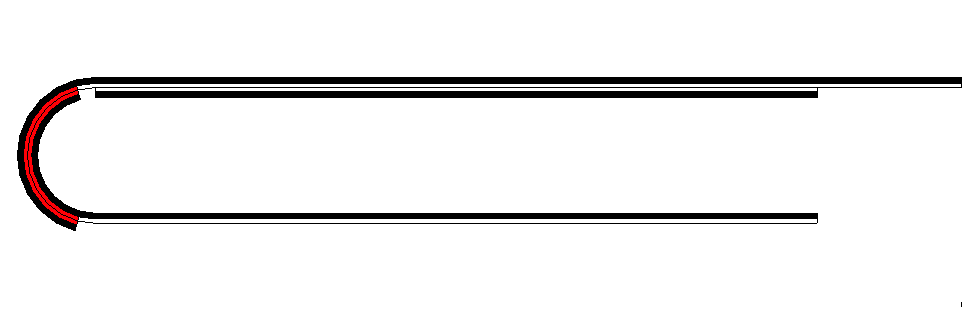

We want the TPU sides of the two rings to face in the same direction, so we’ll have to overlap the edges like this in order to make a TPU to TPU bond, shown below in red:

Start by lining up the centerline of each of the two coaming rings, overlapping the outer edges by 1 cm, TPU to TPU, and then seal a short straight section together:

Continue sealing the two rings together as shown in the video, doing your best to match up the corners. This is the most challenging part of this project, so take your time, and don’t worry if you have to iron in a small wrinkle now and then to force the corners to line up.

To make things easier, you may find it worthwhile to create a 1 cm wide form to drape the fabric over, but I didn’t bother.

Continue sealing all the way around until you have a single ring with a C-shaped cross-section, as in the “bicycle tire” picture above. Check the weld and revisit any areas that need more ironing.

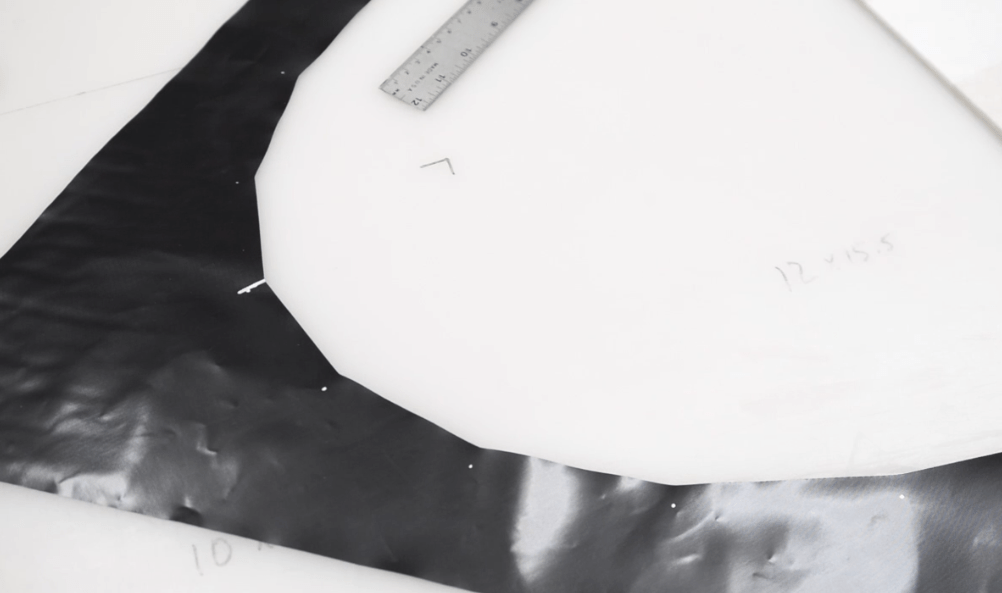

Set the coaming ring aside for now. Measure and mark 1 cm out from each corner of the cockpit hole on the TPU (shiny) side of the spray deck fabric, as in the picture below. A silver permanent marker works well on the black fabric (these areas will not be visible on the finished deck).

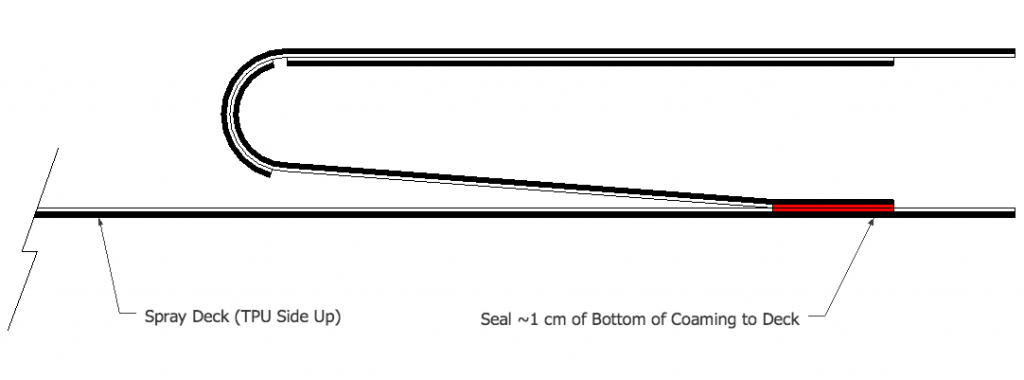

Align the coaming over the cockpit hole with the wider ring on top and the exposed TPU facing down. Your coaming ring “bicycle tire” shape may be inside out after sealing the two rings together, so turn it right side out if necessary.

The bottom ring should line up easily with the marks you made on the deck fabric, 1 cm from the cockpit opening.

Tack the bottom of the coaming ring to the spray deck in a band about 1 cm or half an inch wide, all the way around the cockpit opening. You don’t have to get a perfect seal here yet, because we’ll iron it from the bottom later.

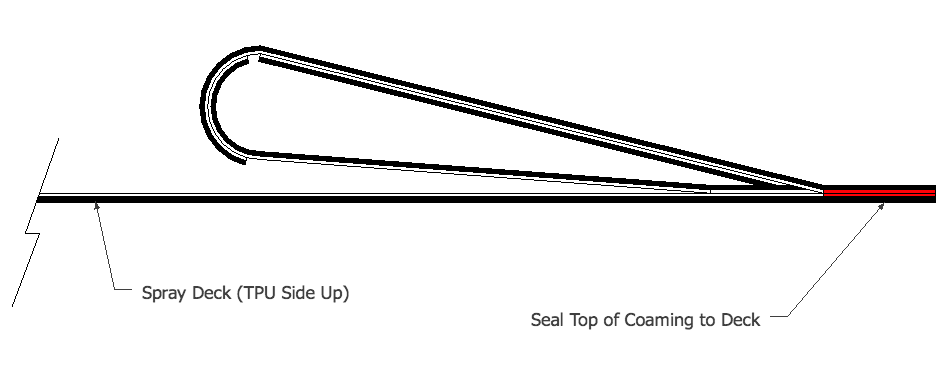

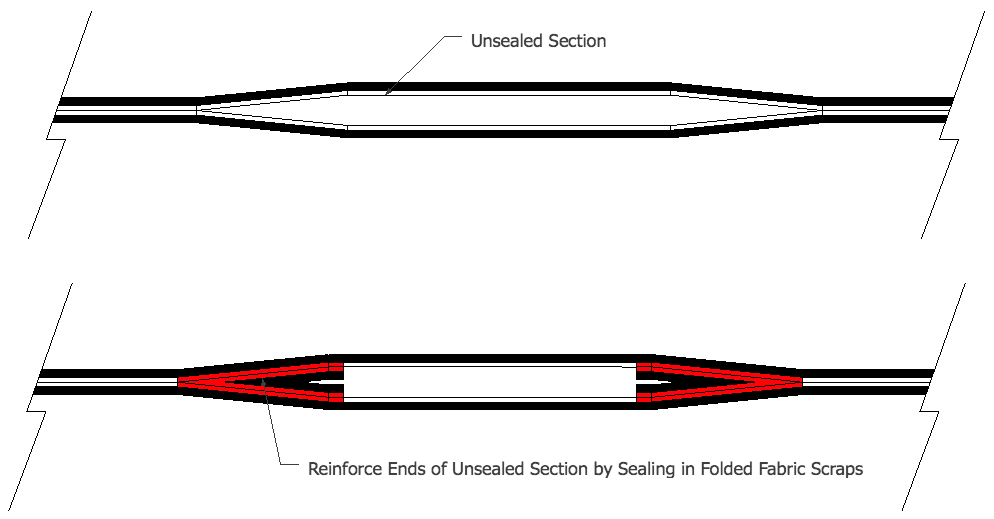

Then seal the top of the coaming to the deck fabric. Leave one of the straight sections un-sealed on either the left or right side of the cockpit to create an opening through which you’ll be able to insert and remove the plastic tubing later on.

Once you’ve ironed all the way around the cockpit, flip the deck over so you can iron it from the bottom as well. Use the full width of your iron so you can seal the deck fabric to both coaming rings. Just remember not to seal over that one section of the top ring we want to leave open. You could slide some parchment paper in there to prevent the layers from being welded together, or mark it with your pen.

Reinforce each end of the short opening you left for the reinforcing tube by ironing in a small fold of scrap fabric. Fold it in half with the TPU on the outside of the fold, so it seals to both the deck fabric below and the coaming ring above.

You can insert similar reinforcing pieces between the deck fabric and the underside of the coaming ring as well. The more whitewater you expect to encounter in your adventures, the more reinforcing you should add here.

Now you’re ready to attach the deck to your packraft.

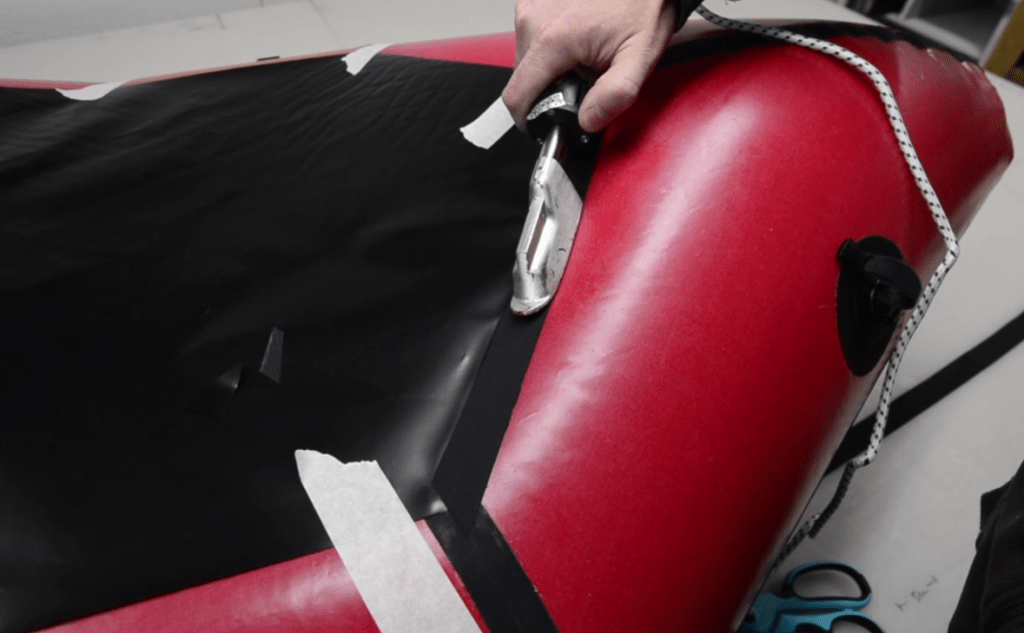

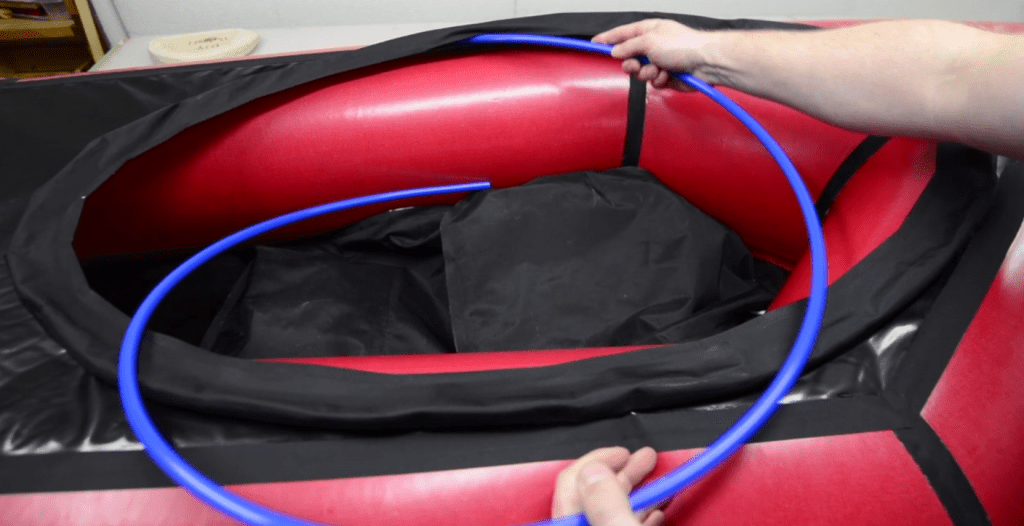

Inflate the packraft and align the corners of the deck fabric over the seam strips. Use masking tape to hold the deck in place, and adjust it until you’ve eliminated as many wrinkles as possible.

Cut seam strips to fit the edges of the deck, and use them to join the deck to the inflated tube fabric. The strips should be centered over the perimeter of the deck, so half of each strip seals to the deck fabric, and half seals to the tube fabric.

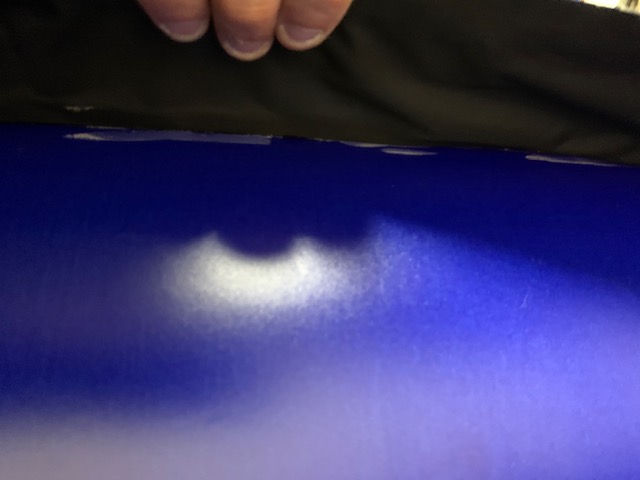

Caution: Avoid holding your iron in one place for so long that the heat transfers through the seam strip and the spray deck fabric to melt the TPU on the packraft’s tubes below the deck fabric (see images below) – this may cause the tubes to leak. If in doubt, practice getting the timing right on some scraps of fabric before beginning to iron the seam strips in place. You can also slide a folded piece of parchment paper between the deck and tube fabric while you are ironing – this will insulate the tube from the heat of the iron. If you do end up with a leak in an area of damaged TPU below the deck fabric, apply some Seam Grip+WP there to stop the leak.

Work your way from one end of the packraft to the other, removing and adjusting the masking tape as necessary, to create a nice smooth deck.

Note: In the demonstration video, the ring around the inflation valve interferes with the spray deck, but I’ve updated the recommended valve location to prevent this from happening, so it shouldn’t be a problem for you.

Slide the plastic tubing into the coaming through the slot you left un-sealed, and trim the tubing by cutting off one short piece at a time until it fits tightly in the sleeve when the ends are butted together, without being too difficult to insert and remove.

Note: Newer kits have different coaming stiffener tubing and a different connector than the ones shown in the video/pictures.

Note: Avoid storing the coaming stiffener tube tightly coiled for long periods of time.

Note: You will want the stiffener tubing to fit tightly inside the coaming sleeve, so only remove a very small amount at a time and then test the fit before removing more.

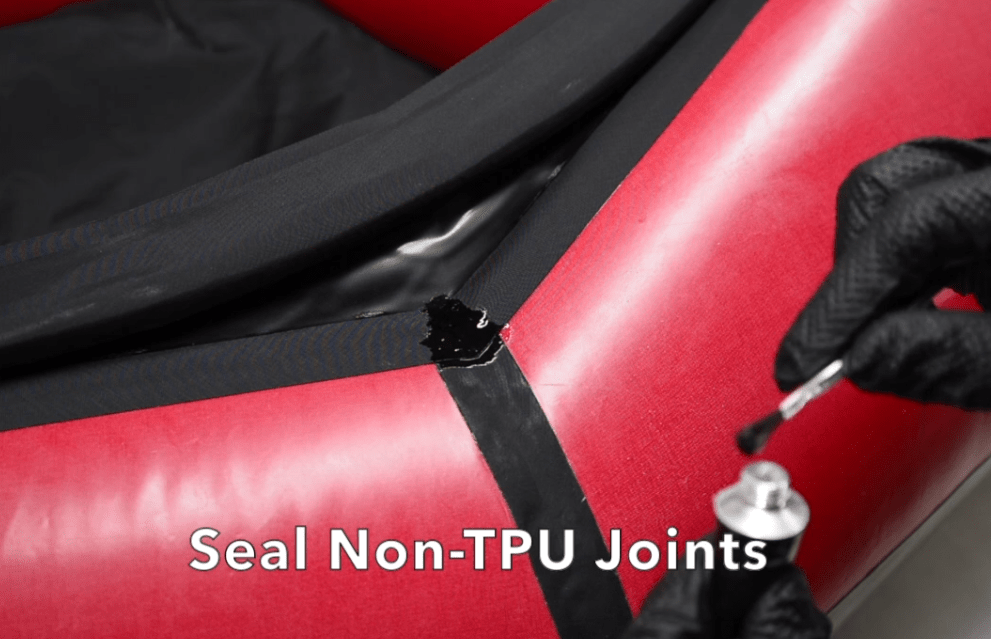

To create a watertight seal at the corners of the deck where TPU-to-TPU welds aren’t possible, you’ll need to use an adhesive such as Seam Grip+WP, Aquaseal, or Aquasure. Tape the corners down while the glue cures.

Now your spray deck is finished! If you haven’t done so already, assemble the spray skirt next.

Questions? Leave a comment below!

22 Comments