- This topic has 8 replies, 4 voices, and was last updated 4 years ago by .

-

Topic

-

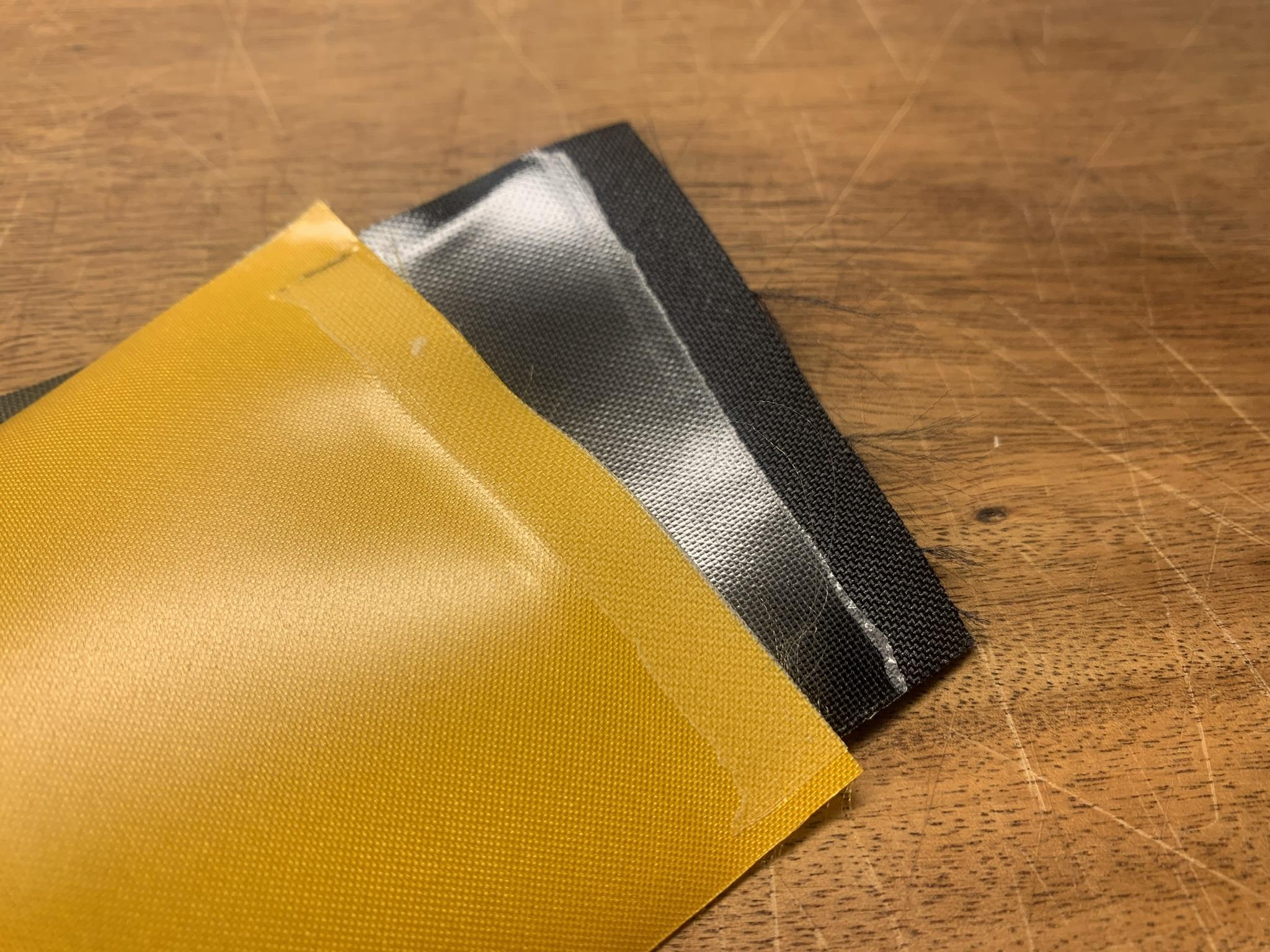

Started attaching 3R today (Skeena build). It seemed to go ok but the tube material isn’t uniformly darker across the entire seam (some parts are darker with a shine – others are less so). Not sure if this is ok or if I need to do more?

Also seem to have overheated the bottom TPU slightly in one area. I’m thinking it’s fine on both counts but would appreciate anyone with experience commenting?

I did some tests prior to this, have made the inflation bag and seat, and all seemed to be ok with those. Maybe I’m just being overly cautious?

Viewing 3 reply threads

Viewing 3 reply threads

- You must be logged in to reply to this topic.