- This topic has 0 replies, 1 voice, and was last updated 5 years, 3 months ago by .

-

Topic

-

Oops! Yes, you can fix even the biggest of mistakes!

I’ve helped with dozens of DIY packrafts. I’ve built my own V2, V3 and a Voyager Tandem. Perhaps it was just a matter of time before I got going too fast and made a major blunder – exactly the kind I explain “not to do.”

I fully installed the right tube section 4R where the left one (4L) should have been. Oops!

I didn’t think I could re-use the piece of fabric I had installed in the wrong place, so I used the remaining piece as a pattern and cut out a new 4R from spare fabric and installed it on the right side, where it should have been.

I had to think long and hard about removing the 4R tube panel incorrectly sitting between the 3L and 5L. Here’s what I learned.

The key is to heat the uncoated side of the fabric you will discard, allowing heated TPU to peel from it and not from the fabric remaining on the raft.

Practice it on scrap fabric first. The goal is to reheat the piece of fabric you will discard and get a feel for the least amount of heat you need to peel apart. It is important to heat the side you will discard. Heating the nylon fabric enough to melt the TPU may cause some of the TPU layer to peel from the heated fabric and remain on the cooler unheated fabric, making the TPU coating thicker.

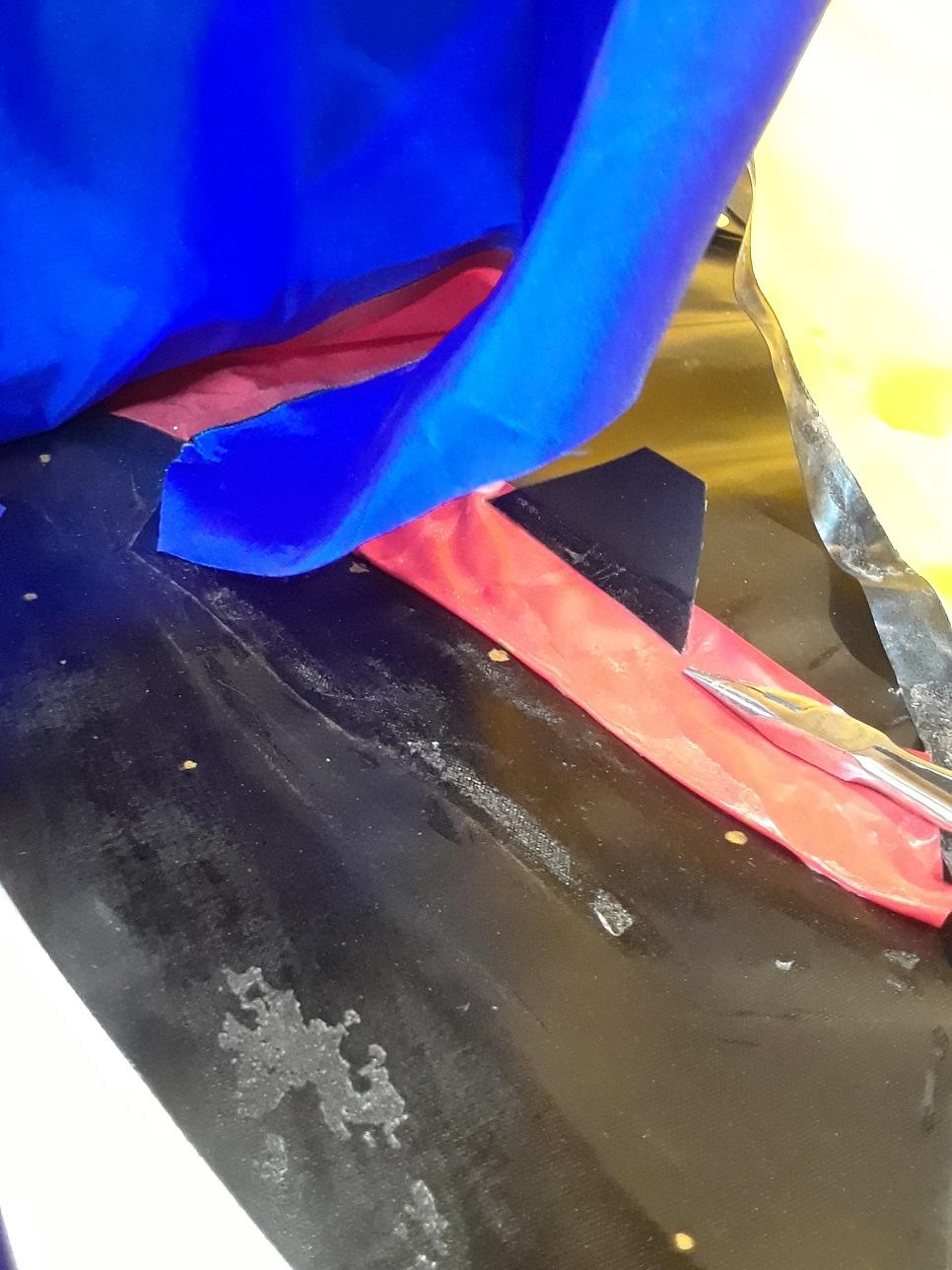

In these photos I am removing the blue fabric (4R). To do so I heated the uncoated side of the blue fabric, peeling it off the 2-sided 420D black floor and the red inside reinforcing strip. The long thin pliers were very helpful tugging at hot fabric close to the hot iron.

You can see patches of whitish TPU coating that has peeled off the blue fabric and remained on the black floor. The photo doesn’t show it well, but I was even able to re-use the 8cm wide red reinforcing strip that was on the floor.

Heating only the blue fabric that will be removed.

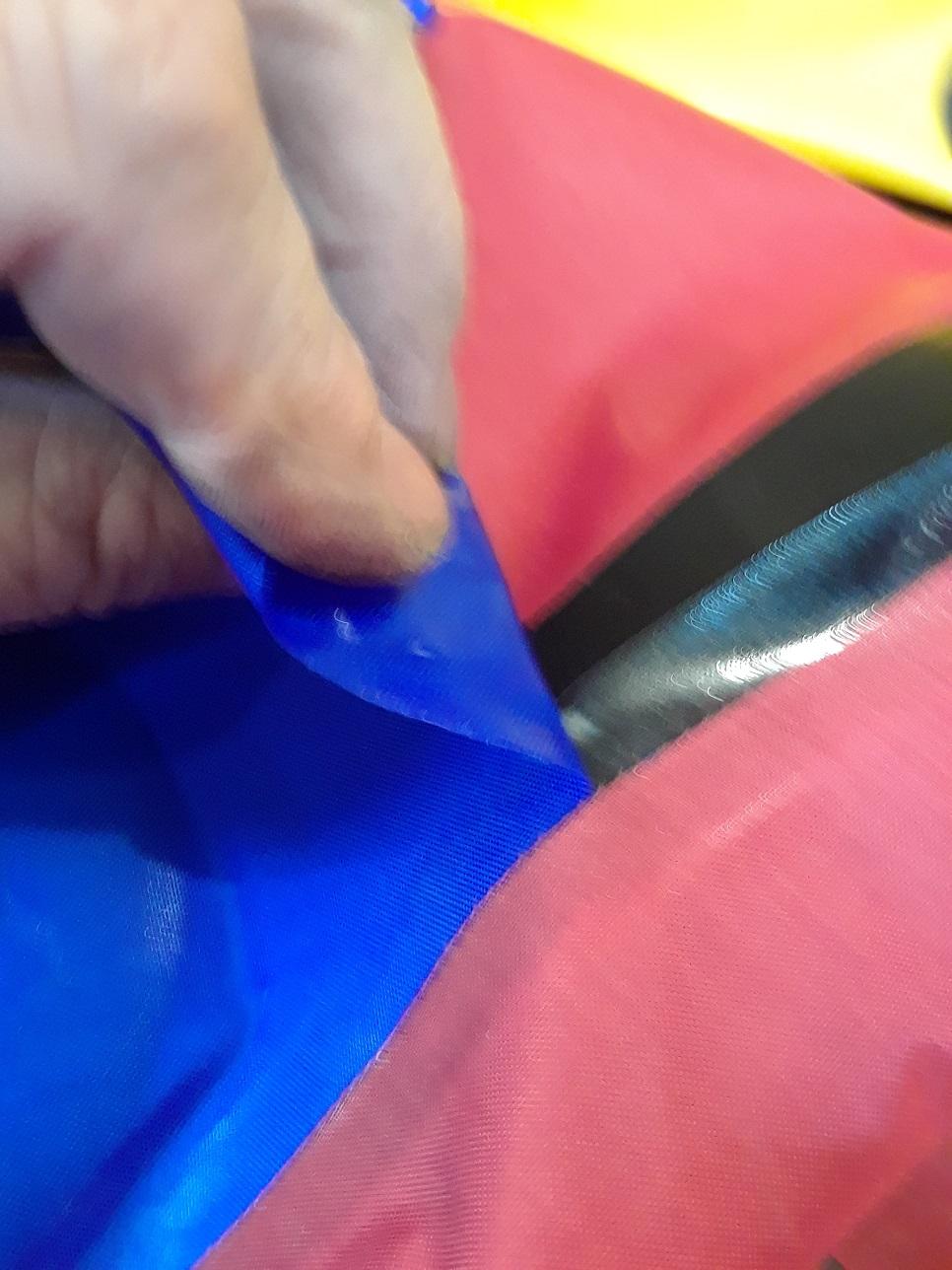

Quickly peeling off the blue fabric while it is hot. An inch or two at a time.

The blue fabric was removed from the black seam tape, the black 420D two sided floor, and the 40D inside red reinforcing strip (which has a 420D tab that will be hole punched for a floor tie down point). The thin nosed pliers were valuable help tugging at threads and lifting and peeling edges of the hot fabric.

I was able to install the correct 4L section onto the old black seam tape and the floor. Exactly where the old panel was incorrectly located. There were a few thick patches where the TPU had peeled off the discarded fabric onto the seam strip – but it welded the second time just fine. The old panel was definitely for the scrap pile. Yes, I added seam sealer the length of the seam!

I used the raft last summer, and the rewelded tube section held just fine.

Much easier to go slow and not make this sort of mistake!

Bruce

- You must be logged in to reply to this topic.