Hi Sean, I’ve found that the TPU to non-TPU welds aren’t very strong, and with all the rolling and unrolling a packraft goes through, it probably won’t hold forever, so I’d put some Seam Grip (or similar) around the edges so if it does separate there at least it won’t leak. The seam sealing glue isn’t great as a structural adhesive either, though. For that you’ll need a different glue. People have told me that HH-66 works well, and there’s another one whose name escapes me at the moment… I think it starts with a “B”. Also, 3M makes some permanent adhesive tapes that work on the fabric. I don’t have personal experience with any of those things though.

It’s hard to say how the part that was unsealed and then resealed will perform… it sounds like only part of it had the TPU separate from the woven fabric when you unsealed it, so it should be okay strength-wise, but again, I’d probably give that area a coat of Seam Grip – not so much for strength, but to prevent any leaks from developing.

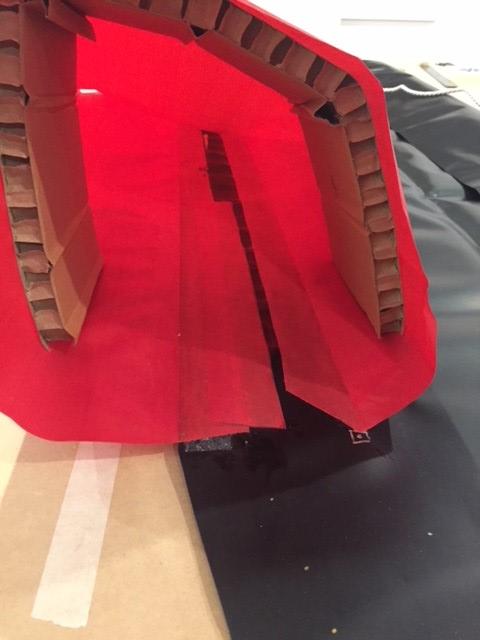

When in doubt, I like to bend and fold the welds sharply several times to make sure nothing separates. There’s going to be lots of bending and folding every time you roll up your packraft after it’s done, so it needs to be able to handle those stresses without any problems developing, and it’s much easier to fix things while you’re building than after it’s done.

I can’t even count the number of hours I’ve spent figuring this stuff out… I think it was around 200 hours before I decided to make a website in 2015. Since then I’ve had lots of help and tips from great people around the world though, and that’s helped a lot! The masking tape trick is a perfect example – a guy named Mike in Seattle was the first to suggest it, and then Bruce in Fairbanks was the one who really showed me the light by actually sending me a wooden form with tape on it so I couldn’t possibly ignore it. There are some really great people in this little community!