Before we close up the packraft’s tubes, we need to install an inflation valve.

Start by deciding where you want to locate your Boston valve. I chose to put mine near the top of the left-rear tube so it will be out of my way when I’m paddling but also easily accessible – 35 cm (14″) from the tip of the stern, and 12 cm (5″) from the longer curved side of piece #5.

I’m going to wait to install my top-up valve until after I can inflate the packraft, so I’ll be able to figure out the best place to put it.

Mark a circle 4 cm (1 9/16”) in diameter in the spot you have chosen for your Boston valve, and cut the circle out with a pair of scissors.

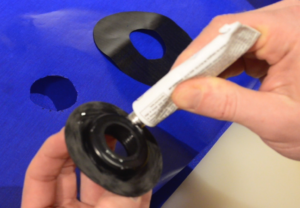

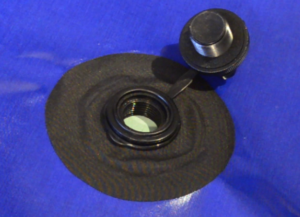

If your Boston valve is assembled, unscrew the one-way valve from the flange, gently remove the plastic ring that holds them together, and set aside the one-way valve. Then use a piece of sandpaper to roughen both sides of the thin plastic flange.

Clean off the dust and then spread some glue onto the roughened surface on the side that has the three raised bumps on the thicker central portion (the side that will be inside the boat, opposite to the lip where the ring attaches), and place the valve in the hole from the “outside” side of the fabric. You can raise the fabric using a roll of tape or some other ring-shaped object so the valve fits down into the hole.

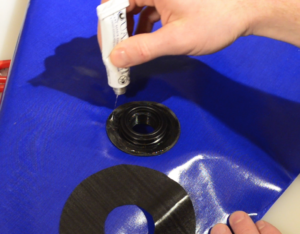

Next, cut a circle of fabric approximately 10 cm (4”) wide, and remove a 4 cm wide circle from its center to form a ring of fabric.

Spread some glue around the exposed side of the roughened plastic flange, and then place the ring of fabric over the valve, TPU side down, and press it onto the glue so the flange on the valve is sandwiched in between two layers of fabric with glue sticking it to both.

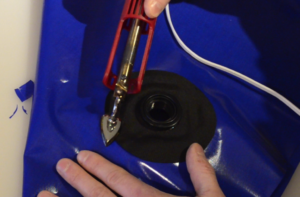

Allow the glue to cure before heat-sealing the fabric ring onto your packraft. Then, if you like, you can add a bit more glue around the valve on the inside of the packraft for extra security.

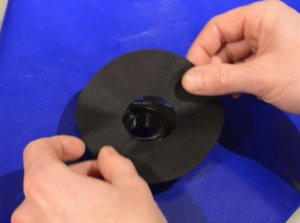

Once the glue has cured, force the plastic ring onto the flange and screw in the one-way valve.

Questions? Please post a comment below.

12 Comments

powerboil · January 10, 2019 at 12:57 am

If i use TPU Boston valve. it’s mean i no need scrub by sand paper or glue?

thank you

Matt (Admin) · January 10, 2019 at 11:51 am

That’s correct – please follow these instructions instead: https://www.diypackraft.com/construction/how-to/instructions-ultralight-ul-kits/install-heat-sealable-boston-valve/

JJ · March 11, 2018 at 6:01 am

I find a roll of toilet paper works well for support when gluing 🙂

Jeb · April 6, 2017 at 12:57 pm

The new style (black) top-up valves heat seal very nicely, no need for glue on those. Just heat seal them to a patch and seal that patch to the boat. Glad Matt was able to source these, they are the same ones Alpacka uses and are flexible and won’t crack/break in the cold.

Matt (Admin) · April 6, 2017 at 8:04 pm

Awesome! I was hoping that would be the case, but I haven’t tried it yet myself. Thanks, Jeb!

nick kelly · February 27, 2017 at 12:10 pm

What make of valve please? The ones sold by Walmart for tubes seem to assume valve seat is present and have no flange’

Thanks

Matt (Admin) · February 27, 2017 at 12:16 pm

Here it is: Boston Valve

Oskar · December 16, 2016 at 1:00 pm

do you think I might also use Aquasure?

http://divezone.pl/pl/klej-do-skafandrow-mcnett-aquasure-tubki-2-x-7-g-p-2403.html

Matt (Admin) · December 16, 2016 at 1:23 pm

Yes – I have not used it yet myself, but I think it will work well.

Peter · December 16, 2016 at 6:51 am

What kind of glue do you use?

Matt (Admin) · December 16, 2016 at 7:22 am

Hi Peter, I’ve been using AquaSeal and it works well. Cheers!

Peter · December 17, 2016 at 6:25 pm

Thanks!